Positek linear displacement sensors provide motorway structural monitoring13 July 2021

A major UK-based structural health monitoring systems company were called in to urgently evaluate problematic expansion joints on a reinforced concrete motorway bridge. It required not just rapid delivery of several linear displacement sensors but also a combined accuracy, temperature stability and environmental specification that would be beyond the capabilities of most suppliers, said Positek.

Within a week, Positek delivered around 40 custom-built sensors featuring a unique differential coil design with electronic temperature compensation and IP68 protection (protected against submersion for long periods). Based on Positek’s PIPS non-contacting sensor technology – an alternative to LVDT and potentiometric displacement sensors – the sensors are said to deliver consistently high accuracy linear position measurement in the harshest environments.

The expansion gap on a typical road bridge is expected to linearly expand and contract by around 1 mm over a temperature range of -20 to +35°C. To precisely monitor abnormal non-linear gap movement in both vertical and horizontal planes and in real time, the overall accuracy offered by the sensors had to be excellent. Due to mechanical expansion as well as a temperature shift in the sensor electronics, it was decided to custom-modify the standard coil design of Positek’s S115 series linear displacement sensor and integrate thermal drift compensation to boost precision and temperature stability.

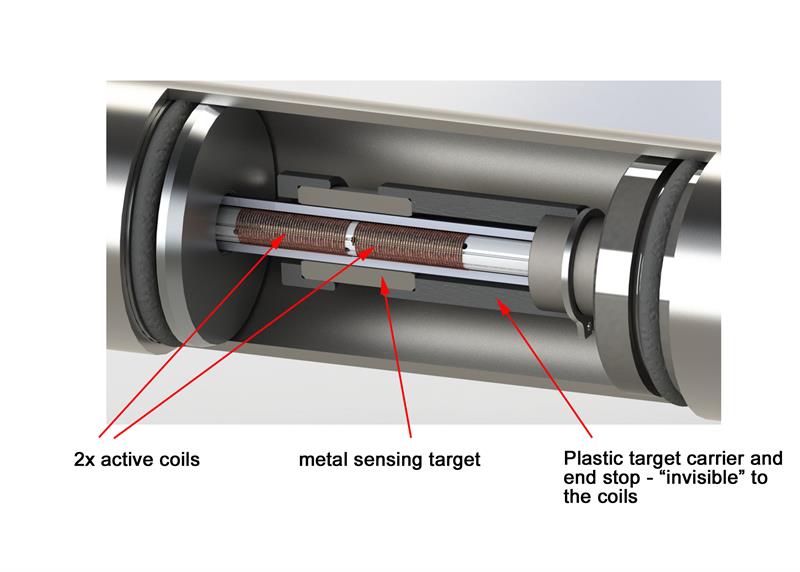

The standard PIPS coil design features a fixed reference coil, an active coil and a one-piece metal target. The custom modification introduces a second active coil in place of the reference coil with a metal target spanning both coils. This differential layout was further enhanced by modelling the sensor’s thermal coefficient and factoring the values into temperature compensation electronics that was integrated into main housing. Sensors with a 5mm displacement range were supplied for the application and arranged vertically and horizontally on brackets supplied by the customer. The modified design can be supplied with displacement ranges as low as 1mm. As well as improve the measurement linearity over the temperature range, the modification also increased the gain by a factor of three and reduced the electrical noise by two to three-times - which was of benefit for the multiple measurement instrumentation system the customer developed for the application.

The 35 mm diameter push-rod sensor used for this challenging measurement task was housed in 316 stainless steel and sealed to protect the sensor electronics against rain, road salt and sea water corrosion, as well as the potential for frosts and high humidity. As with the standard PIPS technology design, this custom differential model is contactless and offers a long working life.

For this application, the custom sensors included industry-standard 4-20 mA outputs with continuous proportional and absolute output with no need for additional signal conditioning. M8 rod-eye bearing fixings and cable gland/flying lead electrical connections facilitated straightforward commissioning.

Operations Engineer

Related Companies

Positek Ltd

This material is protected by MA Business copyright

See Terms and Conditions.

One-off usage is permitted but bulk copying is not.

For multiple copies

contact the sales team.