The lack of lubrication of this greased joint presents a serious risk of the joint failing with the potential for complete collapse of the arm, leading to possible death, serious injury or damage to process equipment and subsequent loss of containment, HSE said.

It adds: “Anyone using or servicing MLAs should check, review and identify inspection and maintenance work required by the manufacturer and industry guidance. Plan how the work will be conducted (including the parts that are difficult to access) and ensure it is completed. Records should be kept and outstanding actions should be followed up.”

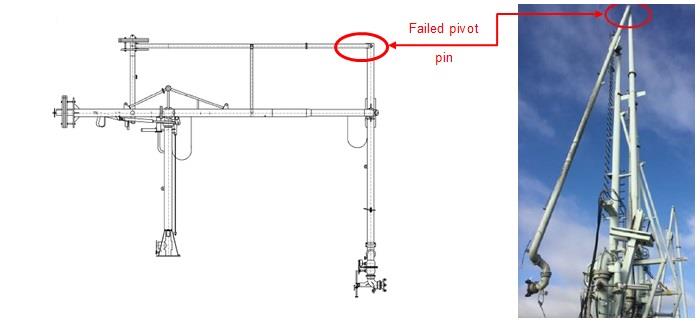

In particular, the eight-inch nominal bore, hydraulically-operated MLA involved in the incident had been in service for 11 years and had been regularly maintained by various recognised industry contractors. It had a rigid link pantograph balancing system with independent primary and secondary counterweights linked to the inboard and outboard arms.

The MLA failed as it was being manoeuvred towards a ship manifold for connection. A section of the MLA fell backwards onto a jetty handrail, narrowly avoiding live plant and pipework on an upper-tier COMAH establishment.

Investigation found that a failed pantograph pivot pin led to the resulting collapse of the arm.

The immediate cause of the failure was from corrosion of the bearing that led to a complete fracture, emanating from the circumference. The underlying causes were inadequate inspection and maintenance practices which had led to the corrosion. There was no convenient means of accessing the pivot pin for inspection and maintenance. As a result, it had not been lubricated during servicing by several different contractors, HSE found.

It adds: the failure to properly inspect and maintain an MLA could result in a serious risk of a joint failing, allowing the pantograph arm to fall – with the potential of causing death, serious injury or damage to process pipework. A review of MLA designs suggests the problem of access to all parts requiring maintenance may not be specific to one manufacturer. Anyone using or servicing MLAs should use a structured management system to ensure they have adequate inspection and maintenance preventing a possible catastrophic failure.

HSE offered specific inspection and maintenance guidance for such structures, below, according to its ‘plan-do-check-act’ sequence for safety intervention.

Examine what is in place and identify areas that need to be addressed (Plan)

- Establish what inspection and maintenance work is recommended by the manufacturer and relevant industry guidance

- Review inspection and maintenance activity carried out

- Determine any parts of their MLA that have not been suitably maintained

Identify areas at risk and prioritise accordingly (Do)

- Update the inspection and maintenance plan accordingly

- As soon as practicable, inspect structural components such as the pivot pin and seals, ensuring they are in good condition

- Implement the updated inspection and maintenance programme, ensuring it is suitable and sufficient, and capable of detecting and remedying any foreseeable deterioration before it results in unacceptable risk

Evaluate the work (Check)

- Verify the work has been undertaken satisfactorily

- Assess that risks are being adequately controlled

- Ensure that a clear, detailed and accurate record of the work is made

- Highlight any servicing requirements that are not carried and make a judgement regarding the potential impact

Review your performance (Act)

- Learn from what was found, taking action as necessary

- Review issues arising from inspection and maintenance and take suitable remedial action

- Review industry good practice and manufacturer’s guidance as well as inspection and maintenance plans periodically to see if they need updating