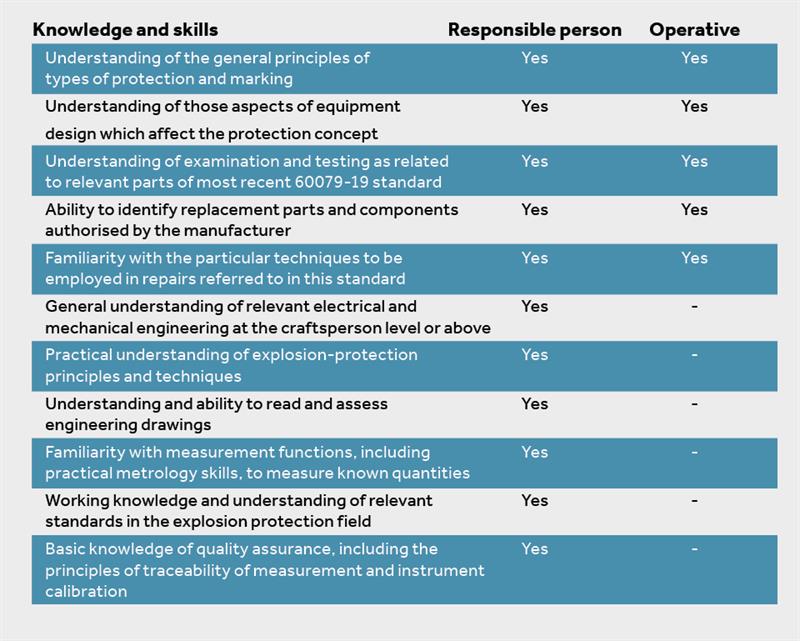

The knowledge and skills required to service and repair Ex equipment such as electrical rotating machines and other associated equipment rests on two distinct categories of personnel, as highlighted in the IEC 60079-19 standard: the operative and the responsible person. This, along with many other requirements, is mandatory for IECEx certified service facilities to maintain their status. However, it should be noted that to repair Ex equipment being IECEx accredited is not mandatory.

Nonetheless, an Ex service centre should have at least one responsible person, which is usually the manager or supervisor in charge of the workshop where the servicing of Ex or hazardous area equipment is conducted.

The responsible person should be trained to understand the different protection concepts of the equipment, how that concept works, what repair procedures can be carried out within that concept, and what repair restrictions are imposed by IEC 60079-19. This will allow them to fully support the operatives and verify the work being carried out. The responsible person should also ensure that the correct records are kept and that the appropriate quality control systems are in place for all Ex repairs.

They should also be able to ensure that the correct calibrated tools and test equipment are being used, the relevant standards are being followed and appropriate certificates are presented.

Operatives are the engineers and technicians that carry out the service and repair of the hazardous area equipment. They should have attended an appropriate Ex repair training course, such as those provided by the AEMT, to fully understand the different protection concepts of the equipment they are servicing, and, as already stated, what restrictions those concepts have when a repair is required. The AEMT is one of many training providers, but specifically focusses on the repair, overhaul, and reclamation of rotating machines.

Both responsible persons and operatives must be able to provide sufficient evidence that they are fully conversant with the theory, skills and practicalities of the Ex work they are involved with. They should regularly attend AEMT refresher sessions (usually every three years) on the repair and overhaul aspects of Ex equipment. This means that all those companies listed within the AEMT Ex-Register remain up to date on both the practical aspects of Ex repair and any changes in the associated standards and legislation, be they ATEX or IEC.